Long-awaited efforts to reduce a controversial petrochemical plant’s impact on the local community have taken a step forward with the approval of a new ground flare.

Fife Ethylene Plant at Mossmorran, operated by oil giant ExxonMobil, has secured permission from Fife Council to install the enclosed ground flare.

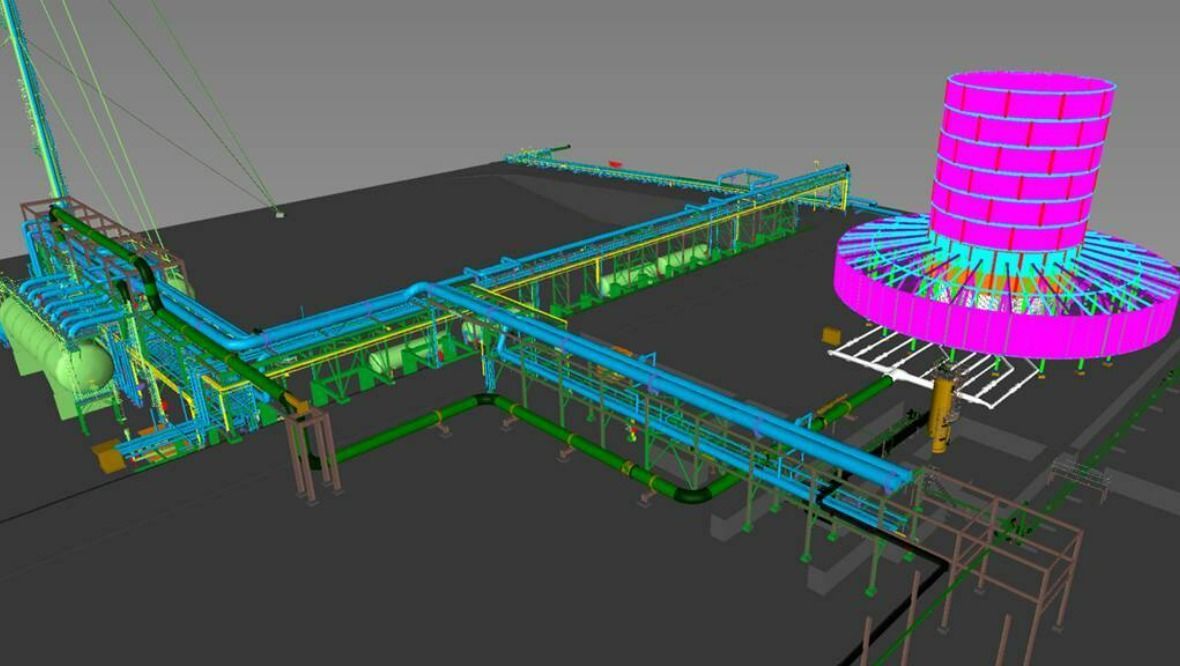

Standing at 31m high, the EGF, as it is known, will “significantly minimise” the use of the existing elevated flare to burn off excess gas – an issue that has concerned Cowdenbeath and Auchtertool residents for years.

Exxon claims it will cut use of the elevated flare by up to 98% – but the stack will remain for use in extraordinary events.

LDRS

LDRSExxonMobil has been forced to flare gas on a number of occasions in recent years for safety reasons. Both it and Shell, which operates the adjacent Fife Natural Gas Liquids plant, were served with final warnings by environment watchdog Sepa in 2018.

Last year, incidences of flaring were referred to the Crown Office for potential prosecution under environment laws.

“The EGF is designed to enclose the flames which reduces visibility and provides acoustic insulation,” agents for ExxonMobil said in a statement.

“This technology has been identified as best available to minimise noise, vibration and smoke associated with flaring and whilst there may be some light emission from the top the effects will be less than the existing Shell ground flare technology or the elevated flare.”

Assessments carried out by independent analysts suggest a “very significant reduction” in noise levels and “negligible” other effects from the ground flare.

Fife Council planners agreed, noting the flare would “limit the adverse environmental impact” of elevated flaring. They approved the application with a handful of conditions to ensure safe construction and operation.

Approval of the flare comes weeks after ExxonMobil completed £140m of upgrades to the plant that bosses promise will reduce flare-related disruption in the interim as installation of the new facility takes place.

These upgrades include a new tip for the elevated flare that uses internal steam tubes to reduce the amount of noise emitted by the flare. However, reliance on the elevated flare will fall dramatically once the EGF is in place.

LDRS

LDRSPlant manager Martin Burrell said in a statement issued last month that over 48,000 parts had been installed over the course of 500,000 people-hours to improve reliability at the plant and reduce the need to flare.

Addressing locals directly, Mr Burrell said: “We thank you and our communities for your patience while we completed our major upgrade project and plant restart.

“We hope that the actions we took to minimise elevated flaring, as well as the benefits of the new flare tip helped to reduce disruption to local communities.

“While we are confident the project will help to improve operational reliability and reduce unplanned flaring, FEP is a complex operation with our flare remaining a vital operational and safety system.”

However, locals in the surrounding towns remain hostile to Mossmorran’s continued operation.

Last weekend saw residents and climate activists gather outside the plant to call for a green transition at the plant, ensuring workers keep their jobs while progress is made towards clean energy production.

ExxonMobil says it is committed to reducing carbon emissions. However, unlike other firms in the sector such as Shell and BP, the firm is yet to commit to a solid net-zero target.

By local democracy reporter Jon Brady

Follow STV News on WhatsApp

Scan the QR code on your mobile device for all the latest news from around the country

LDRS

LDRS